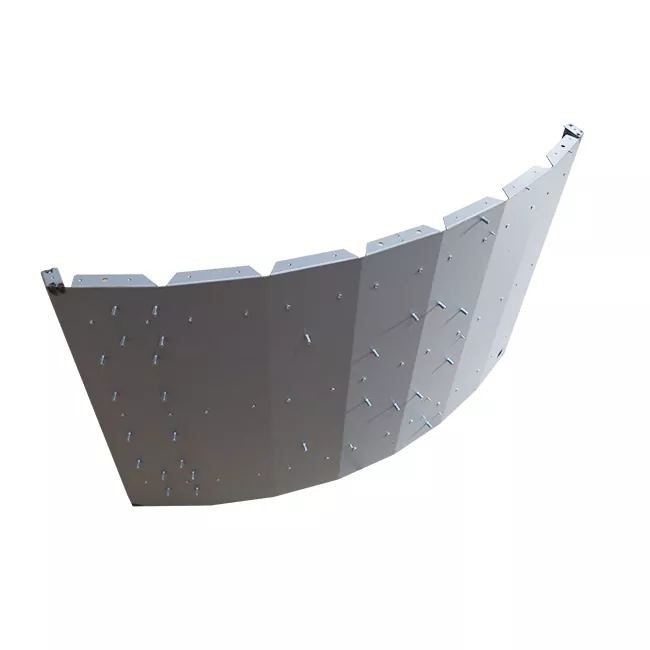

Sheet metal parts with curved surface structure are being used more and more in the fields of industrial equipment, electronic product shell, automatic control system and display terminal.Compared with traditional planar structures, curved sheet metal not only has a more modern appearance, but also has obvious advantages in structural strength, space utilization and overall stability.Relying on many years of experience in sheet metal manufacturing, Xinyang focuses on providing high-quality Curved Sheet Metal solutions to customers around the world to meet the multiple needs of precision, strength and reliability in different industries.

Curved surface structure in industrial products is not simply for beauty, behind which is often a comprehensive consideration of structural performance and functional integration.The curved sheet metal parts produced by Xinyang are widely used in the following fields:

Industrial control equipment and industrial control box shell

LCD display and man-machine interface housing

Electric control cabinet, power cabinet and communication equipment

Switches, network equipment and electronic terminals

Medical equipment and precision instrument housings

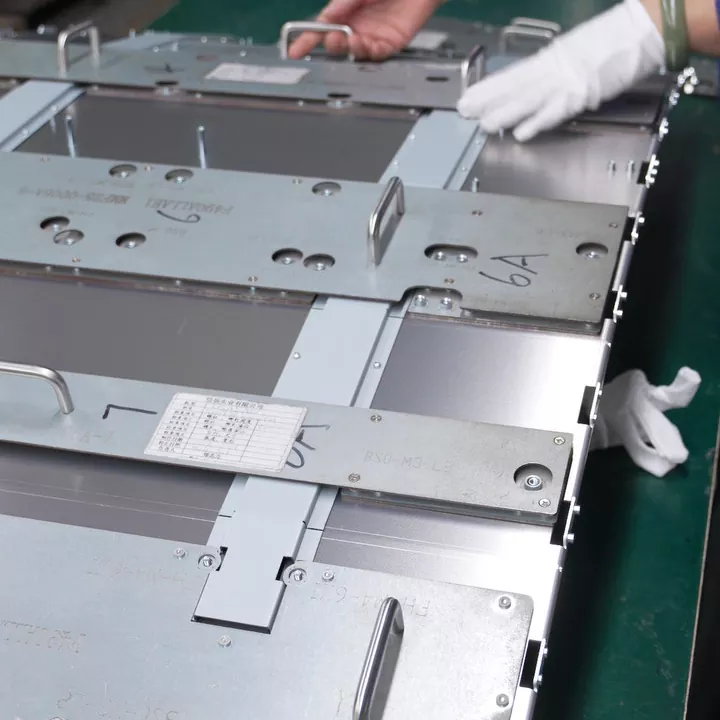

Through our proven Curved Sheet Metal Manufacturing process, we are able to achieve stable mass production from simple arcs to complex multi-segment curvature structures, ensuring that each product maintains good consistency during assembly and use.

The core difficulty of curved sheet metal lies in forming accuracy and structural stability.Xinyang, as a professional Sheet Metal Manufacturer located in China, has established a complete manufacturing process from design evaluation to batch delivery.

In the early stage, we will conduct manufacturability analysis on curvature radius, development size and tolerance requirements according to drawings or samples provided by customers to ensure the feasibility and stability of subsequent Curved Sheet Metal Processing.In the production process, relying on AMADA CNC punch, CNC bending machine and laser cutting equipment, accurate blanking and forming control are realized to avoid surface deformation and stress concentration problems.

For products with high appearance requirements, we can also support spraying, silk screen and surface treatment processes to make the curved surface transition natural and smooth, meeting the aesthetic and durability requirements of the end market.

To help customers understand product capabilities more intuitively, the following is the technical parameter range for common surface sheet metal (can be customized according to the project):

| Project | Technical Parameter Range |

| Material Type | Cold-rolled steel, stainless steel, aluminum alloy, galvanized steel |

| Material Thickness | 0.8mm – 3.0mm |

| Radius of Curvature | ≥ 5mm (depending on material and structure) |

| Dimensional Tolerance | ±0.1mm ~ ±0.3mm |

| Surface Treatment | Powder coating, painting, electroplating, brushing, anodizing |

| Protective Performance | Corrosion resistance, compression resistance, dustproof design |

| Manufacturing Method | Custom processing / Processing based on provided drawings |

These parameters reflect not only the machinability of Precision Curved Sheet Metal, but also our level of control in terms of batch consistency and long-term stability.

In a global sourcing environment, customers focus not only on price, but also on suppliers 'ability to deliver consistently and ensure quality.As a China Sheet Metal Factory with more than ten years of experience, Xinyang's advantages are reflected in many aspects:

Experience precipitation: Since its establishment in 2016, it has focused on sheet metal parts manufacturing and served many industries such as communications, medical care, and electric power.

Complete equipment: 100+ professional processing equipment, covering cutting, forming, welding and surface treatment

Team stability: 50+ skilled manufacturing personnel, long-term engaged in sheet metal processing practice

Quality system: strictly implement the quality policy of "quality first, delivery on time"

Customer recognition: the product has been adopted by many famous enterprises at home and abroad for a long time

These fundamental capabilities make us not only a Supplier, but also a long-term partner who can participate in the product development phase of customers.

Is curved sheet metal suitable for mass production?

With the mature Curved Sheet Metal Manufacturing process, curved sheet metal is also suitable for medium and large volume production with good consistency as long as the curvature and material selection are properly controlled at the design stage.

Does surface structure affect strength?

Reasonable design of curved surface structure in most cases can improve the overall rigidity, reduce local stress concentration, especially suitable for industrial control box and electronic control equipment.

Do you support customization and drawing processing?

Xinyang supports fully customized services, which can be developed according to customer drawings, samples or application scenarios, covering materials, structures and surface treatments.

Is delivery and communication stable?

As a direct customer contact China Manufacturer, we have a complete factory system, which can effectively control the production cycle and provide clear project tracking services.

Based on the advantages of China manufacturing, Xinyang continues to provide stable and cost-effective curved sheet metal products for overseas customers.We not only pay attention to the delivery of single orders, but also pay more attention to technical support and quality continuity in long-term cooperation.Through professional Curved Sheet Metal Processing capabilities, we help customers shorten product development cycles and accelerate market layout.

If you are looking for a reliable Curved Sheet Metal Supplier, Xinyang will be your reliable choice with solid manufacturing strength, rigorous quality standards and pragmatic cooperation attitude.

Phone: +86-13600283195

Mobile: +86-13600283195

E-mail: xy@dgsxy.com

Address:No. 243, Miaobianwang Road, Shipai Town, Dongguan City, Guangdong Province, China

Copyright © 2025 Dongguan Xinyang Industrial Co., Ltd. All Rights Reserved.